- ConProLink system comprising VF master and VF slave with KVLSH 162 AL system

- Calibre range 10 to 28 mm

- Portion length from 80 mm

- Belt speed: max. 0.65 m/sec.

- Portioning capacity: max. 300 portions/min. (depending on product and lengths):

- Minimum hook spacing: 20 mm

CONPROLINK

Perfectly linked ConPro products with closed, well-formed ends

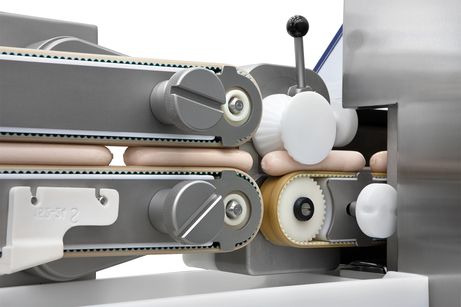

The ConProLink system enables the continuous production of products with closed ends. The ConProLink technology produces an alginate casing using the linking/co-extrusion head, portions the filling product accurate to the gram, constricts it in equal lengths with the help of the voider and links the products.

Linking with optional cutting or hanging

The individual, linked portions can either be cut and processed further in horizontal position (e.g. fine sausage meat and dry sausage products with well-formed, closed portion ends) or a defined number of them can be transferred to the hanging unit in loops, with the required distance between them.

ConProLink for the hanging of products

The hanging function takes the production of ConPro sausages to another level and creates additional potential for innovative product solutions and highly-economical processes. An optimally adapted hook makes it possible, for example, to hang snack products very close together (cal. 8 and cal. 10). Smoking chambers are therefore utilised to a significantly higher degree, thus resulting in cost savings.

Full automation due to product handling

A wide variety of product handling options complete the automation process. Further processing steps for hung products include conventional smoking and cooking systems and, with cut products, they include collating and depositing into packaging solutions or transferring to continuous smoking/cooking/baking systems.

Top advantages

- Excellent product appearance due to closed ends

- Processing semi-viscous products is possible due to

completely closed product ends - For a variety of applications, such as meat, cheese, fish, confectionary, vegetarian, vegan, kosher and halal products

- Excellent product shelf-life due to ideal hygiene conditions

- Existing smoking/cooking systems can be used for hung products (e.g. salami sticks)