Fast casing spooling thanks to casing end detection

A special feature of the PVLH 226 is the casing end sensor for casing end detection. The linking nozzle automatically moves into the spooling position for quick and easy application of new casing onto the linking nozzle.

Exact portioning by means of flexible voider technique

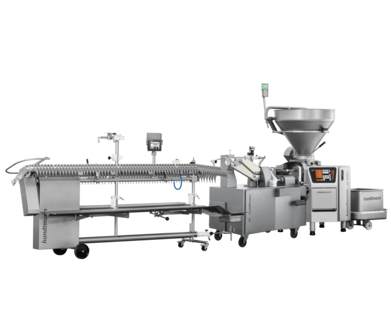

The compactly designed PVLH 226 features portioning using a flexible voider technique. This provides extraordinary accuracy in terms of portion weight and length of the sausages.

Premium product quality with high productivity

The semi-automatic casing change function with one linking nozzle enables the industrial-scale production of sausages in all types of casing, including natural casing products. Despite the high output, all sausages are well-filled and of exactly the same length.

Economical, ergonomic and reliable hanging

Simplified hook placement also cuts setup times. Excellent ergonomic working conditions thanks to the hanging unit’s individually adjustable height. Increased output thanks to more efficient smoke stick utilisation and reduction of give-away thanks to the integrated Handtmann smoke stick scales on the hanging unit.

Top advantages

- High production output and short conversion times thanks to semi-automatic casing change and digital setup assistant

- Start-up assistant for natural casing to guarantee reliable operation and a perfect product from the first portion

- Portioning with voider technique possible for natural casings up to calibre 38/40

- Well-filled sausages with optimum product quality and appearance

- Product diversity thanks to large range of applications and calibres for all types of casings and sausage meat

- Portion weights accurate to the gram for all products, also in natural casing

- Increased output and reduction of give-away thanks to integrated Handtmann smoke stick scales on the hanging unit